During Winter Quarter 2025, I enrolled in a metal fabrication course to become more confident in the metal shop, learning to safely operate every major tool and translate digital designs into physical products.

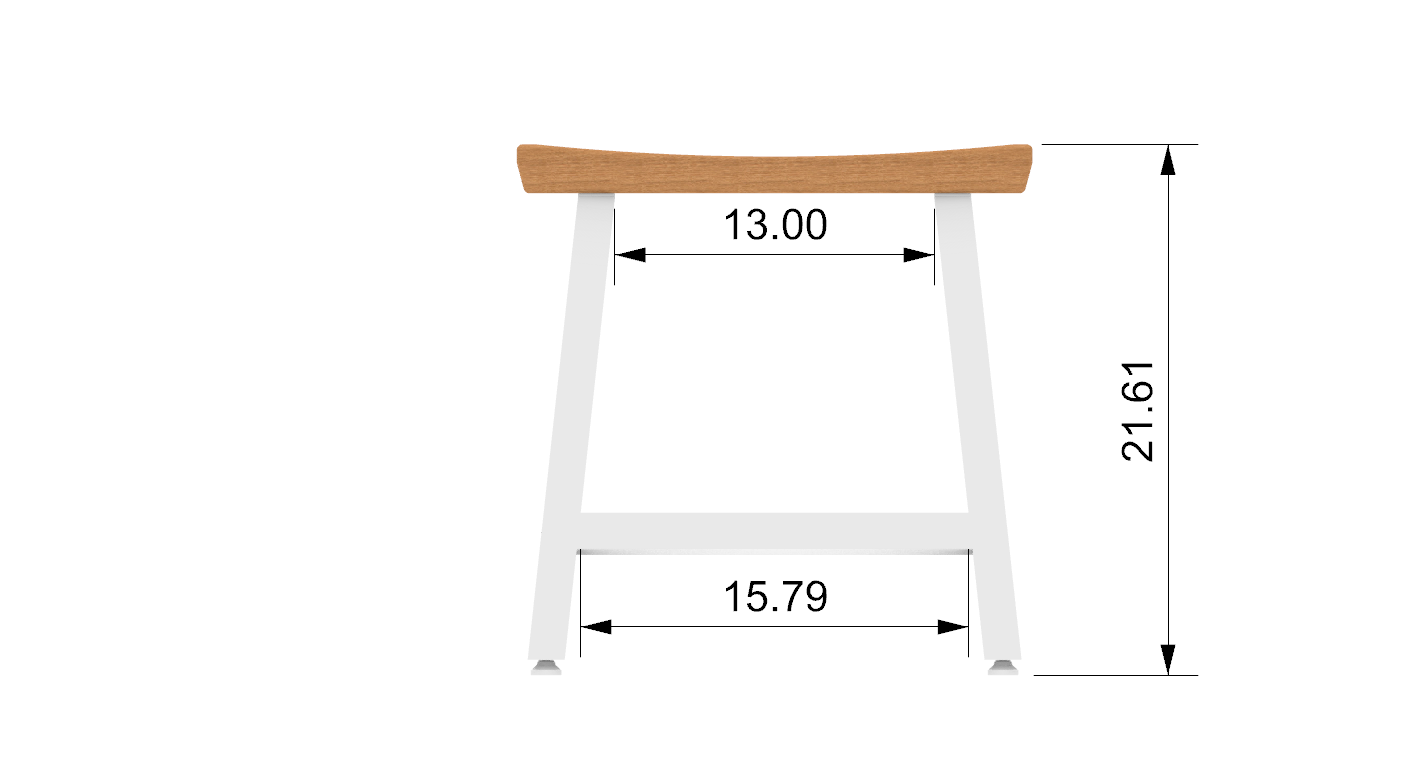

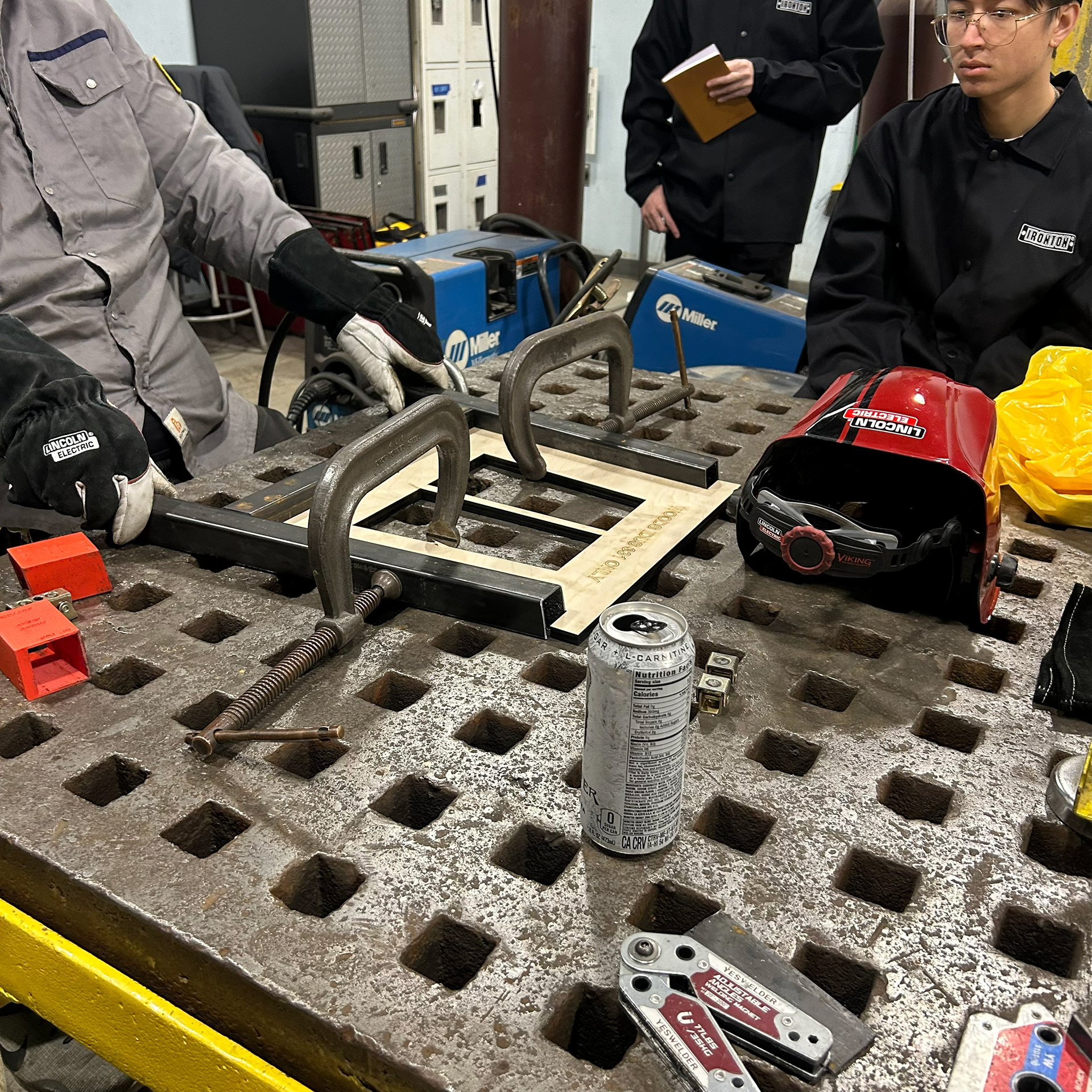

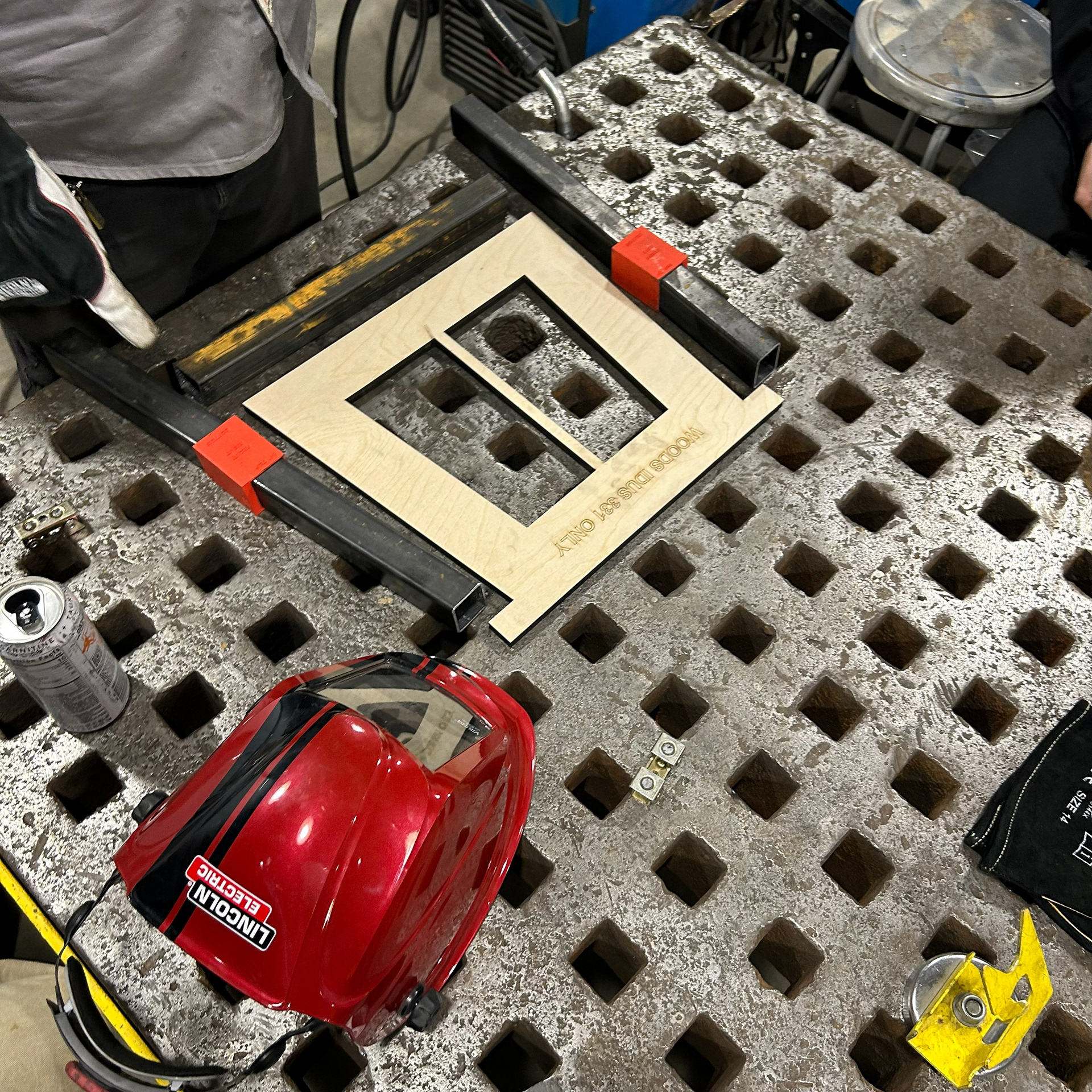

Our first assignment was a replication project. Our professor provided a CAD model of a small metal chair, and we were tasked with creating a precise physical duplicate. This meant:

Taking meticulous measurements from the reference model

Planning each cut and bend before touching the material

Practicing accurate layout marking on metal stock

Using tools like the bandsaw, belt sander, drill press, and welding equipment

Checking tolerances and adjusting along the way

After recreating a standard stool, I realized there was always more possibility in its form — more room to build, expand, and transform. That led me to introduce 3D-printed LEGO-inspired studs to the surface of the chair. The studs change the chair from a static object into a modular system, something that can continuously evolve through play and imagination.

With the studs, the chair becomes connective rather than fixed. You can attach new pieces, extensions, and accessories. To demonstrate this, I created a stud-based hanger attachment capable of holding real weight. I showcased this by hanging a tote bag filled with books and magazines — proving that the chair is not just playful, but truly functional.

This chair asks a simple question:

Why shouldn’t everyday furniture be playful, adaptable, and personal?

Why shouldn’t everyday furniture be playful, adaptable, and personal?

“Legofying” the chair turns it into more than seating — it becomes a creative platform, a piece of furniture that can grow and change with the user. It encourages curiosity, interaction, building, experimentation, and storytelling. The chair becomes both object and activity — something you continue to shape, rather than something finished.